Affordable Price,

Unmatched Consistency,

Overall Reliability,

True Accuracy

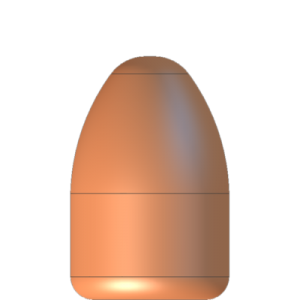

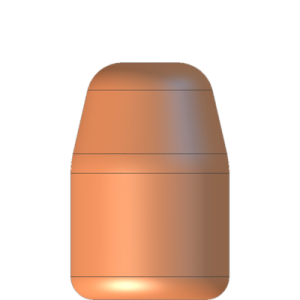

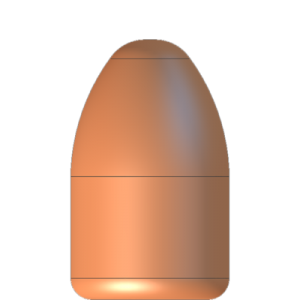

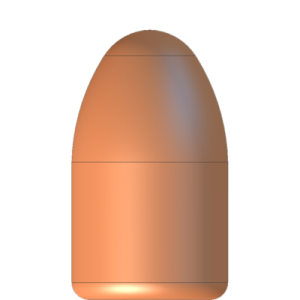

Our DistributorsCopied by many, matched by none. Frontier CMJ Bullets are world famous, not only because they are affordable, but also due to their unmatched consistency, overall reliability and true accuracy. CMJ Bullets are fully coated in pure copper. The core consists of lead antimony and the CMJ design allows for zero jacket and core separation. The majority of our CMJ Bullets are restruck resulting in increased consistency and overall accuracy. Restriking is the process of forcing the already plated bullet into a shaping die and ensuring the form of the bullet is exactly in line with the design. Thus, no production markings or deformities will remain. Also, restriking ensures that each bullet is precisely the same as the one before. Switch to the Frontier CMJ’s and experience why top international shooters choose CMJ’s above all else!

Why is jacketing so important?

- Lead exposure

- CMJ’s have other advantages as well as the prevention of barrel fouling.

- Better visibility during shooting, due to elimination of smoke caused by bullet lube.

- A very important factor is costing – the manufacturing process of CMJ’s as opposed to FMJ’s allow much better pricing and especially in a sport that requires the firing of hundreds of rounds during a match, or for practice.

In the age of health awareness and pollution, the problem of exposure to lead vapour has become a much- discussed subject in the shooting sports. Lead poisoning is a very real danger and it can cause serious health problems, including brain and kidney damage. Other symptoms of lead poisoning are often noticed but not readily diagnosed for what they are, as shooters never think about informing their GP’s of excessive exposure to lead vapour.

Results of studies in the USA confirmed that 89% of shooters tested , exceeded the permissible limit for occupational exposure to lead.

Outdoor shooting poses a much lower risk of being overexposed to lead vapour but Indoor ranges however is a different scenario and the problem of lead vapours is real.

The jackets of traditional metal jacket bullets only cover part of the bullet – the base of the lead bullet core is still exposed to hot gasses, causing the formation of lead vapour as the ammunition is fired. Complete Metal Jacket bullets, also marketed as “‘lead safe bullets” have no exposed lead surfaces to come into contact with hot propellent gases. CMJ’s are covered with pure electrolytic copper jackets that cover the entire surface of the bullets. Over the years Frontier Projectiles have developed their own, unique and very successful plating process with the help of the company that provides most of the company’s chemicals to ensure maximum efficiency and ultimate core bonding.

To try Frontier Projectiles please contact us or our Distributors.